Manual Handling – How’s Your Technique?

Test

Ask an employee to explain good lifting techniques. Also check there is no unnecessary manual handling.

Reason for This Question

Staff must not be allowed to carry out any manual handling tasks without having had manual handling training.

Possible Answers

Red: Staff could not demonstrate safe lifting techniques

Amber: Staff able to demonstrate safe handling, but no training records found

Green: Staff able to demonstrate safe handling and good training records in place

Common Issues

- No training records available.

- Observations saw many examples of poor manual handling techniques.

- Processes not documented

- Manual handling training is provided as part of induction however but no refresher training.

Fail Rate

18% of businesses failed this question based on our sample data.

Information

What is manual handling?

Manual handling is defined as “The supporting and transporting of a load by hand or bodily force”

- Lifting or lowering

- Carrying

- Pulling

- Pushing

Under the Manual Handling Operations Regulation 1992 it is every employer’s duty to carry out a risk assessment for each manual handling task or activity.

Before completing a risk assessment as employer you need to ask:

Can this activity/task be eliminated? Does it have to happen?

Manual handling policy

It should be policy that all team members receive manual handling training on induction and training prior to commencement of any duties involving manual handling.

Poor manual handling is one of the biggest single causes of injuries in the workplace.

Injuries include pulled muscles and strains, damage to the structure of the back, damage from dropping loads onto feet or trapping hands between loads and fixtures, and falls when trying to move loads.

Examples of manual handling include:

- Lifting stock up to and down from stockroom racking,

- Carrying stock into a stockroom area from a delivery vehicle,

- Pushing or pulling out a trolley,

- Putting out the waste,

- Handling equipment that needs to be physically moved.

High Risk Activities

Good manual handling practices can help to prevent and minimise accidents and injury.

People are different!

The ability to carry out physical work such as manual handling will vary between employees, e.g. with age, sex, fitness, etc. and also for the same person over time, e.g. as they age, become more or less fit, suffer injuries or illness.

- Never assume that everyone is capable of a particular task,

- In general, young persons, females, less physically fit persons, and team members with lighter physiques can handle fewer loads, in a safe manner, than a mature, male, fit, physically strong person.

Certain conditions can make persons more susceptible to manual handling injuries, even if they might otherwise be considered likely to be capable of a particular task. These include:

- pregnancy and nursing,

- any existing upper limb problems,

- any existing back problems,

- Hernia, etc.

Safe Manual Handling Guidance

If possible manual handling of loads will be avoided altogether.

It is unlikely that all manual handling can be avoided but it might be possible to remove the need for some tasks.

If handling cannot be avoided use of mechanical aids should be considered to reduce the amount of physical effort required.

For a specific task then management will need to complete a task specific lifting and carrying risk assessment form or the task specific pushing and pulling risk assessment form which is held in the health and safety records folder or can be printed from PYRAMID™ under the health and safety menu ->health and safety records option.

Any team member who feels they have any impairment that may affect an ability to carry out manual handling safely, should inform their duty manager.

Where team members will have to use physical effort in manual handling the following general precautions must be followed:

- Anyone carrying out manual handling will be trained in good handling technique,

- Individuals must not attempt to handle loads that are beyond their capabilities,

- If necessary, loads should be broken down to a more manageable weight, especially in cases where help from another team member is not available,

- Help should always be sought from other team members to move heavy or awkward objects that cannot be split into smaller, or more manageable, loads. These team members must be briefed on the findings of the risk assessment.

- Sensible footwear which gives a good grip and allows for good balance must be worn.

How to avoid manual handling:

- Does it need to be moved?

- Can contractors be used?

- Contact your management if issues arise and that cannot be resolved.

- Smaller and more manageable loads/products.

- Can the items be taken direct to their storage area or point of use by the deliverer?

- Can the distance travelled be reduced or be made safer or easier to move things through?

Good Handling Technique – General Lifting

Think before lifting/handling and plan the lift

Think before lifting/handling and plan the lift

- Can mechanical aids be used?

- Will help be needed with the load?

- Can the load be broken down and carried as a number of smaller loads?

- Examine the route to be taken; is it well lit, are there steps or changes in level, are there any obstructions or trip hazards that need to be moved out of the way, etc.

- For a long lift, consider resting the load midway on a table or bench to change grip.

- Look at where the load is to be moved to. Can it be put down safely and easily or is there any need to move other items to create space?

- Are there any sharp edges on the load? If so cover them or wear protective gloves.

- If the load needs to be lifted by straps, are gloves needed to stop these cutting into hands?

- Can the weight in the load move around, e.g. a liquid in a part full container? Unstable loads will be more difficult to handle so the safe maximum load for each person will be reduced.

- Is there anything about the load that might make it difficult to move safely?

Adopt a stable position

- The feet should be apart with one leg slightly forward to maintain balance (alongside the load, if it is on the ground).

- Try to stand close enough to the load to have the centre of weight of the load as close as possible to the body. If the load is on the floor placing feet to the sides of the load can help (having feet square against one side will ‘push you away’).

- Be prepared to move their feet during the lift to maintain a stable and balanced position.

- Avoid tight clothing or footwear which may make this difficult

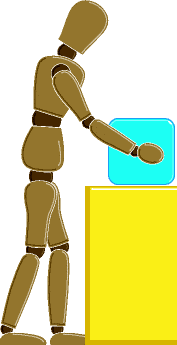

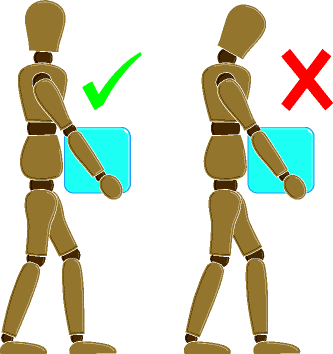

Keep the load close to the waist

- Keep the load close to the body for as long as possible while lifting.

- Keep the heaviest side of the load next to the body.

- If a close approach to the load is not possible, try to slide it towards the body before attempting to lift it.

Get a good hold

- Where possible the load should be hugged as close as possible to the body. This may be better than gripping it tightly with hands only.

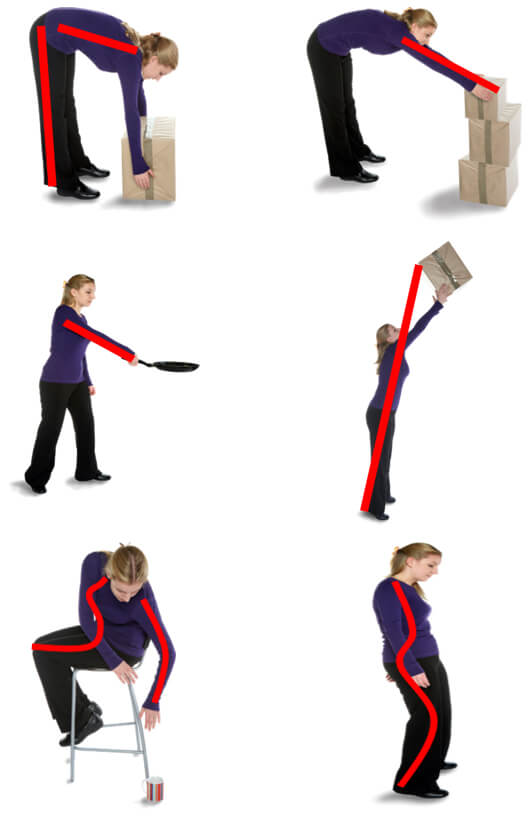

Start in a good posture

- At the start of the lift, slight bending of the back, hips and knees is preferable to fully flexing the back (stooping) or fully flexing the hips and knees (squatting).

Keep the back flexible while lifting

- Do not allow the back to take all the strain though.

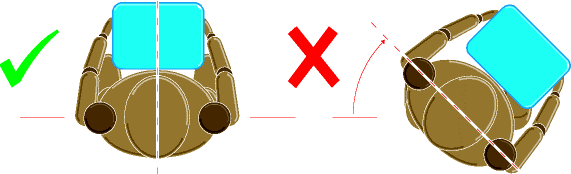

Avoid twisting the back or leaning sideways especially while the back is bent

- Shoulders should be kept level and facing in the same direction as the hips. Turning by moving the feet is better than twisting and lifting at the same time.

Keep the head up when handling

- Look ahead, not down at the load, once it has been held securely.

Move smoothly

- The load should not be jerked or snatched as this can make it harder to keep control and can increase the risk of injury.

Don’t lift or handle more than can be easily managed

- There often is a difference between what team members think they can lift and what they can actually lift safely. If in doubt, seek advice or get help.

Put down the load then adjust

- If precise positioning of the load is necessary, put it down first, and then slide it into the desired position.

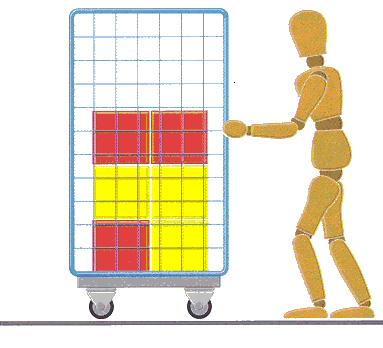

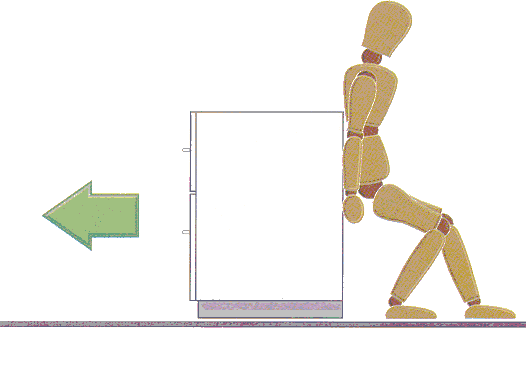

Good handling technique for pushing and pulling

- Push rather than pull a load, provided you can see over it and can control steering and stopping.

- Get a good grip on the item to be pushed or pulled. Hold the trolley between shoulder and waist height.

- Keep their back straight, stomach in, knees bent, and elbows in.

- Lean in the direction you’re pushing or pulling.

- Watch out for obstructions.

- The force required if you have to travel up or down a slope or ramp can be very high. Get help from someone else whenever necessary.

- Keep feet well away from the load and go no faster than walking speed.

- Trolleys must be maintained in good working order, especially wheels.

- Wheels on trolleys must be large enough not to jolt the load, or get stuck, if there are any uneven surfaces.

- Travel over rough or uneven surfaces requires more force, so load weight might need to be reduced.

Guidance for difficult situations or loads

When it is not possible to bend their knees or get close to the object:

- Stand close to the load

- Bend their knees if possible – or brace themselves by putting their knees against a solid object. Use an arm as a supporting strut if this helps.

- Bend at the hips, keeping their head and back in a straight line.

- Lift gradually, using legs, buttocks and stomach muscles.

When more than one person is lifting an object:

- Work with someone of similar height and build if possible.

- Choose one person to call the signals.

- Lift from the hips at the same time, and then raise the load to the desired level.

- Move smoothly and together.

Team handling

When carrying sacks:

- Carry the sack on their shoulder braced by their hand on their hip.

- Alternatively hold it at opposite ends resting the load against you hip and stomach.

- Do not attempt to lift or carry large sacks without assistance.

Avoid one-arm loads where possible, but if you cannot avoid them:

- Brace their body

- Reach for the load, bending their knees and waist, keeping their back straight.

- Grasp the load firmly, using available handles.

- Lift with their legs using their free arm for balance.

- Keep their shoulders level and switch arms regularly.

- Consider carrying a load in each hand to balance the load.

For lifting to a high place:

- Lighten the load if possible.

- Stand on something sturdy, with one foot in front of the other, unless using a stepladder.

- Use a mechanical aid or get help where necessary.

For lowering from a high place:

- Test the weight by pushing the load up. Check if the load will shift when you lift it.

- Make sure there is nothing on the load that could fall off.

- Stand as close to the load as possible.

- Grasp the object firmly, sliding it down their body.

- Use a mechanical aid or get help where necessary.

This post is part of the “Focus on Health and Safety Audit Questions” series. A series which focuses on questions asked by our health and safety consultants when conducting a health and safety audit.

Comments are closed.